Description

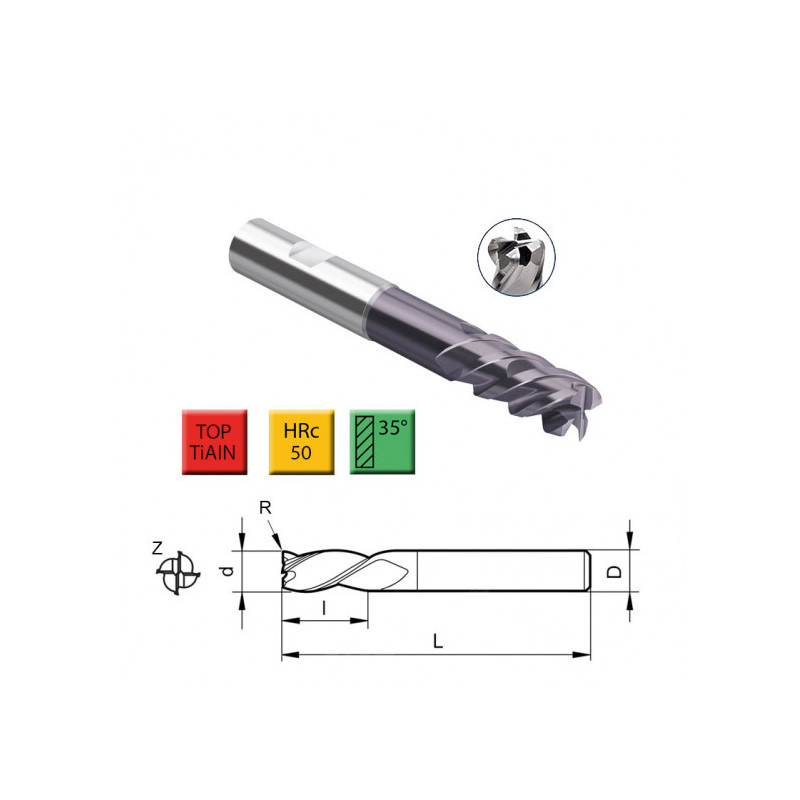

JK Nástroje • Carbide milling cutter 4 teeth 6-20mm • Long version

High-performance milling cutters made of fine-grained universal carbide with high-quality TiAlN-based coating. For material hardness up to 58 HRc.

Available sizes:

| SKU | LET 0604 | HEA 0604 | LET 0804 | LET 1004 | LET 1204 | LET 1604 | EMCA 3X 1604 | LET 2004 | EMCA 3X 2004 |

| Tool diameter (d) | 6,0 mm | 6,0 mm | 8,0 mm | 10,0 mm | 12,0 mm | 16,0 mm | 16,0 mm | 20,0 mm | 20,0 mm |

| Cutting length (l) | 30 mm | 16 mm | 40 mm | 40 mm | 50 mm | 60 mm | 80 mm | 90 mm | 80 mm |

| Shank diameter (D) | 6 mm | 6 mm | 8mm | 10 mm | 12 mm | 16 mm | 16 mm | 20 mm | 20 mm |

| Total length (L) | 75 mm | 75 mm | 100 mm | 100 mm | 100 mm | 150 mm | 150 mm | 200 mm | 150 mm |

| Number of teeth (Z) | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

Applicable for complex materials:

This high-quality carbide milling cutter is designed for machining materials like: stainless steels, refractory steels, chromium alloy steels, nickel-cobalt alloy steels, titanium alloy steels, non-ferrous steels and plastics.

Coating:

High-quality TiAlN-based coating, microhardness (HV 0.05) = 3300, maximum working temperature 900°C, low friction coefficient (dry against steel 0.25)

High durability compared to conventional TiAlN coating.

Suitable for high heat loads (dry machining, HSC)

Purple TiAlN coating is one of the most widely used coatings in modern high-performance machining. TiAlN coatings are resistant to oxidation and allow work to be performed approximately 20 – 35% faster than with TiN coating. The aluminium content of these coatings is approximately 50 percent. TiAlN coating is applicable for machining of abrasive materials such as cast iron and is suitable for dry machining due to its high heat resistance.

JK Nástroje – High-quality cutting tools made in Europe.

Reviews

There are no reviews yet.